10/18/2010 12:22 PM

By WILLIAM HARWOOD

CBS News

The shuttle Discovery's right-side orbital maneuvering system rocket pod during post-servicing installation in July. (Photo: NASA)

KENNEDY SPACE CENTER, Fla.--Engineers are troubleshooting a small fuel leak aboard the shuttle Discovery that will require them to interrupt launch processing and drain toxic propellants from the ship's aft rocket pods before beginning repair work later this week.

The operation will close launch pad 39A for normal operations for two to three days, but NASA officials say enough contingency time remains in the processing schedule to complete the work in time for launch Nov. 1 as planned if no major problems are encountered.

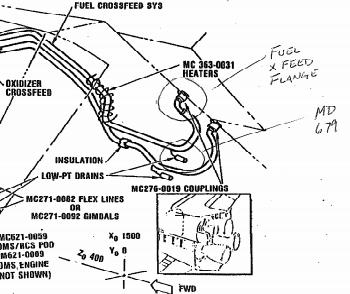

The trouble involves seepage of toxic monomethyl hydrazine, or MMH, fuel at a crossfeed flange in the propellant plumbing of the shuttle's right-side orbital maneuvering system rocket pod. The shuttle is equipped with two such rocket pods, one on either side of the ship's vertical tail fin, that burn monomethyl hydrazine with an oxidizer, nitrogen tetroxide, to carry out maneuvers in orbit.

After testing over the weekend, engineers were able to trace the leak to a specific area of a large flange where two sections of propellant line come together. But it is not yet clear whether the seepage involves a seal in the flange or the flange itself.

The right-side OMS pod was removed after Discovery's most recent flight in April to repair a helium isolation valve in another part of the system. After the pod was re-installed in July, leak checks were normal and no obvious loss of pressure has been noted. But insulation around the flange was found to be damp with MMH over the weekend.

Because the propellants are extremely toxic, repairs cannot begin until the OMS pod tanks are emptied and the propellant lines drained. The going-in plan is to drain the tanks and lines Wednesday and then to replace the seal.

With Discovery in the vertical orientation at the launch pad, removing residual propellant from the lines is expected to be difficult. Even so, engineers believe they can replace the seal and reload the system in time to make the current launch date. Replacing the flange itself at the pad would be much more difficult, engineers say, requiring lines to be cut and welded.